Automation

Components - Systems - Services

Product overview

the spirit of safety

Email liên hệ: info@pilz.vn

Phone: 0946 54 52 53

Các mã Pilz thường có sẵn tại Việt Nam:

PNOZX3, P2HZX1P, PNOZXV2P, PNOZM2e, PNOZ M03p, PNOZ X3P, PNOZ mlp, PNOZ milp, PNOZ molp, PNOZ XV2P, P2HZ X1P, PNOZ XV2P, PNOZ X3P 24VDC 24VAC 3N/0 1N/C 1SO, PNOZ XV3P 3/24VDC 3N/O 2N/O t, PNOZ X3 230VAC 3N/O 1N/C 1SO, PZE X4VP 1/24VDC 4N/O fix, PZE X4P 24VDC 4N/O, PZA(600/24VDC 1N/O 2N/C), PNOZ X7.1 24VAC/DC 1N/O 1N/C, PNOZ X2 24VAC/DC 2N/O, PNOZ6 - 3S/10, PZE/5-24VDC-4S-10, PNE7-6S/10, PMUT X1P 24VDC 3N/O 1N/C 5SO, PONZ X3P, PZE X4P, PONZ XV3P, PNOZ MI 1P, PNOZ 11, PNOZ X2.4V, PNOZ X3, PNOZ X4, PNOZ 11 230-240VDC, PNOZ X2.4V 1/24VDC, PNOZ X3 24VAC/DC, PNOZ X4 230VAC, PZE 9 230-240VAC 8N/O 1N/C, PNOZ X9 200-230VAC 24VDC 7N/O 2N/C 2SO, PNOZ X3 230VAC 3N/O 1N/C 1SO, PX 30 – 6495, PNOZ 11, PNOZ X2.4 V, PNOZ X3, PNOZ X4, PNOZ X3P 24VAC/DC 3NO 1NC, PNOZ XV2P 30/24VDC 2NO 2NO, PNOZ X1P 24VDC 3NO 1NC, PNOZ X2P 24VAC/DC - 2N/O, PNOZX3P 24VDC 24VAC 3N/O 1N/C 1SO, PNOZX7.1 24VAC/DC 1NO 1NC, PNOZXV23/24VDC 2NO 2NO FIX, PNOZXV23/24VDC 2NO 2NO T, PX 120 IBS, PZE 9 230-240VAC 8N/O 1N/C, PNOZ X9 200-230VAC 24VDC 7N/O 2N/C, PNOZ X3P 24VDC 24VAC 3N/0 1N/C 1SO, PNOZ X3P 24-240VACDC 3N.O 1N/C 1SO, PNOZ XV3P 30/24 VDC 3N/O 2N/O T, PNOZ X3 24VAC 24VDC 3N/O 1N/C 1SO, PZE X4P C 24VDC 4N/O, PZA 600/24VDC 1N/O 2N/C, PNOZ X7 110VAC 2N/O, PNOZ X2 24VAC/DC 2N/O, PNOZ X1 24VAC/DC 3N/O 1N/C, PNOZ X1P C 24VDC 3N/O 1N/C, PNOZ M1P, PNOZ MS2P, PNOZ MILP, PNOZ MOLP, PNOZ MCLP, S1UK, PZA 600/24VDC 1N/O 2N/C, PNOZ X7 24VACDC 2N/O, PNOZ X2 24VAC/DC 2N/O, PNOZ X3 24VAC 24VDC 3N/O 1N/C 1SO, PNOZ 6 24 VDC, PZE 5 24 VDC 4S10, PNOZ XV3P 30/24 VDC 3N/O 2N/O T, PZE X4P 24VDC 4N/O, PNOZ X3P C 24VDC 24VAC 3N/O 1N/C, PNOZ X3P C 24-240VACDC 3N/O 1N/C, PNOZ11, PNOZ11, PNOZ XV2, PNOZ X4, PNOZX3P, PNOZ MC3P, PNOZ M1P, PNOZ MILP, PNOZ MOLP, PNOZ MS2P, PSEN SL-1.0P 1.1VA, PNOZM1P-773100, PNOZ-S4, PNOZ X2.4 V 774517, PNOZ X4 24VDC 3N/O 1N/C, PNOZ 11 24VAC 24VDC 7N/O 1N/C, PNOZ MO1P 4 SO, PNOZ MS2P, PNOZ 10 24VDC 6N/O 4N/C, PNOZ MS2P, PNOZ MS3P, PNOZ S5 24VDC 2N/O 1N/C T, PNOZ S7 24VDC 4N/O 1N/C, PNOZ X4 24VDC 3N/O 1N/C, PNOZ 11 24VAC 24VDC 7N/O 1N/C, PNOZ MO1P 4 SO, PNOZ MS2P, PNOZ 10 24VDC 6S40, PNOZ10 24VDC 6S40, PNOZ X4, PNOZ 11, PNOZ XV2 3/24VDC 2N/O 2N/O T, PNOZ S3 24VDC 2N/O, PNOZ S6C 24VDC 3N/O 1N/C, PNOZ S7C 24VDC 4N/O 1N/C, PNOZ S9C 24VDC 3N/O T LN/CT, PNOZ S11C 24VDC 8N/O 1N/C, PSEN CS4.2P, PSEN CS4.1P, PNOZ X4 24VDC 3N/O 1N/C, PNOZ 11 24VACDC 7N/O 1N/C, PNOZ MS2P, PNOZ MS3P, PNOZ S3 24VDC 2N/O, PNOZ X3P 24VDC 24VAC 3N/O 1N/C, PNOZ S11 24VDC 8N/O 1N/C, PNOZ S4 24VDC 3N/O 1N/C, PNOZ S5 24VDC 2N/O 2N/O T, PNOZ S7 24VDC 4N/O 1N/C, PNOZ MC3P, PNOZ M1P, PNOZ MI1P, PNOZ MO1P, PNOZ MS2P, PNOZX3P 24VDC 24VAC 3N/O 1N/C 1SO, PNOZX7.1 24VAC/DC 1NO 1NC, PNOZXV23/24VDC 2NO 2NO FIX, PNOZXV23/24VDC 2NO 2NO T, 773810, 773820, PNOZ S3 750103, PNOZ S6 751106, PNOZ S7 751107, PNOZ S9 751109, PNOZ S11 751111, PSEN CS4.2P, PNOZ S3 24VDC 2N/O, PNOZ S11 24VDC 8N/O 1N/C, PNOZ S4 24VDC 3N/O 1N/C, PNOZ S5 24VDC 2N/O 2N/C T, PNOZ S7 24VDC 4N/O 1N/C, PNOZ M1P 773100, PNOZ X3 774311, PNOZ X3 774311, PNOZ X3P 777310, PNOZX3P, PNOZ X9, PX30-6495 307678, PNOZ 11 774086, PNOZ X2.4V 774517, PNOZ X3 774310, PNOZ X4 774738.

Automation

Components - Systems - Services

Product overview

the spirit of safety

Total customer proximity

Pilz has a tradition as a family-run company stretching back over 60 years. Real proximity to customers is visible in all areas, instilling confidence through indi-vidual consultation, total flexibility and reliable service. Worldwide, round the clock, in 26 subsidiaries and branch offices.

Benefit-oriented innovations

Our customer proximity is the basis for our innovative strength. We are always oriented towards current market requirements, which is why we can offer innova-tive automation solutions in every case. Customer proximity and innovation belong together and are mutually dependent.

Overall solutions

Pilz is your solution supplier for all automation functions. Including standard control functions. Pilz developments protect man, machine and the environment. Our automation solutions incorpo-rate our knowledge and experience from the stringent demands of safety technology, as well as the sum of our knowledge gained from over 60 years' experience of general automation technology. All our experience and knowledge go into individual products and sophisticated system solutions.

► Sensor technology

► Control technology

► Networks

► Drive technology

► Operator and visualisation systems

► Software

► Automation system PSS 4000

► Consulting and engineering

► Training

the spirit of safety

With their knowledge, enthusiasm, creativity and courage to take the unconventional route, our staff have made us what we are today: one of the leading brands in automation technology.

More than 1,400 staff, each one of them an ambassador for safety, make sure that your company's most valuable asset - your staff -can work safely and free from injury.

Safe sensor technology

Components

Pilz sensor technology offers a wide range of components which, in con-junction with Pilz control tech-nology, form a tailored solution and a complete safe, approved system.

Units for safe position monitoring

PSENini

PSENrope

Safety switches

PSENmech

PSENcode

PSENbolt

The safe proximity switch PSENini detects the approach of metallic objects without the use of contacts. It supplies the necessary safe signals via pos-itions and end limits and guaran-tees a smooth production cycle. PSENini can also generate the pulse for counting tasks or for detecting rotational movements.

The safe rope pull switch PSENrope is manually operated and is used to safely shut down functional processes that extend over a wide area, such as con-veyors. It provides maximum safety, as the emergency stop function can be triggered at any point along the rope.

Hazardous machine move-ments must be stopped when a guard is opened. It must not be possible to either defeat or manipulate these guards. PSEN safety switches meet this requirement and are there-fore suitable for monitoring safety gates as well as position monitoring. Thanks to a variety of designs and operating prin-ciples they are flexible to use -individually or in series.

For safety gates that are difficult to adjust or in areas where safety gates are frequently opened and closed, protection must be provided against defeat and manipulation, but a long material service life must also be guaran-teed. PSENbolt provides a com-plete solution, comprising safety switch, handle and bolt.

Safety gate systems

PSENhinge

PSENslock

PSENsgate

The hinge switch PSENhinge is a safe, complete solution comprising safety switch and hinge, and is suitable for rotatable and hinged guards. Designed as one functional and installation unit, it offers a high level of flexibility in installation, connection and adjustment. It can be integrated directly into the safety gate, so that PSENhinge is particularly space-saving and secure from manipulation.

With its combination of safe position monitoring and process guard locking, the safety gate system PSENslock is designed for the highest category applications. The magnetic guard locking device on PSENslock is largely non-wearing, compared with mechanical technologies. PSENslock is also more tolerant to changing environmental conditions, guaranteeing long-term use.

PSENsgate combines safety gate monitoring, safe guard locking and control elements in just one system, guaranteeing the protection of personnel and plant. Additional functions such as emergency stop and escape release are included in the safety gate system PSENsgate. The system is ready to install and reduces the work involved in configuration and installation.

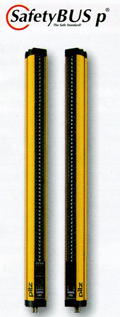

Optoelectronic protective devices

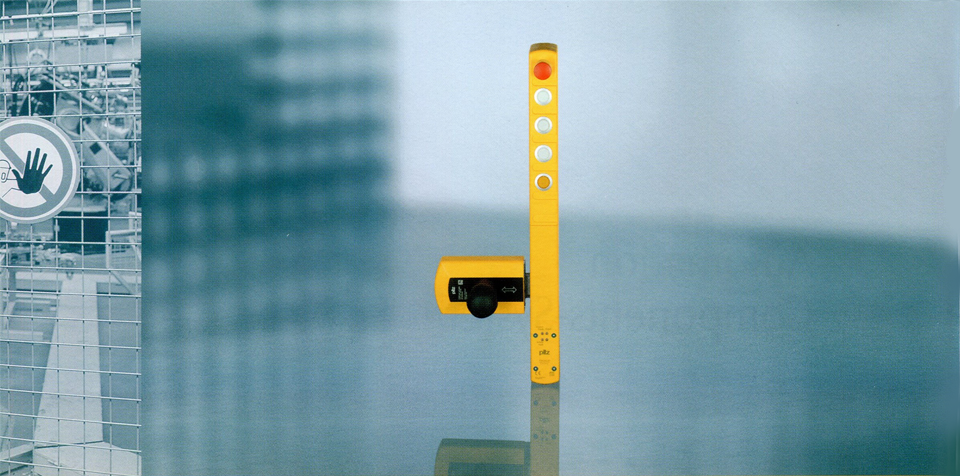

Safe camera systems

PSENopt

PSENvip

PSEN se

If the production process requires active intervention, there is a high potential risk. Safety light beam devices, light curtains and light grids PSENopt offer greater productivity, while safeguarding access to the work process. Muting, blanking and cascading open up a range of possibilities for optimum incorporation of PSENopt into your plant. For complex light grid applications, PSENopt SB with integrated SafetyBUS p interface is the right solution.

The camera-based protection and measuring system PSENvip is a mobile protection device, which can be used to monitor press brakes safely. When installed on the upper die, the system detects even the smallest foreign body in the protected field between the transmitter and receiver. It is also available as a productive version, combined with the control system PSSuniversal PLC from the automation system PSS 4000.

SafetyEYE, the safety technol-ogy for 3D zone monitoring, enables barrier-free protection. It combines intelligent sensor technology with effective con-trol. The SafetyEYE safe camera system detects and reports objects that encroach into warning and detection zones, which can be defined in ad-vance. Its reaction is flexible, based on the requirement. A hazardous movement may be slowed down or brought to an emergency stop, for example.

Control technology

Components

Pilz control technology - for safety and standard! A solution for your automation function - economical, safe and from one source. With compatible components and systems.

Line inspection devices

Relays for electrical safety

Relays for functional safety

PLIDdys in conjunction with PNOZelog

PMDsigma

PMDsrange

PNOZsigma

The safe line inspection device PLIDdys provides safe power-up on two-wire connections, pro-viding maximum safety on long cable routes. With PLIDdys, unintended power-up or plant start-up can be excluded in the event of an error. Plants can easily be retrofitted thanks to an extremely compact design and the ability to loop into the existing wiring.

For electrical safety such as voltage or true power monitoring, electronic monitoring relays provide the optimum solution. They reduce the number of hazardous situations for man and machine and increase the service life of plant and machinery through an efficient production cycle.

PMDsigmaPMDsigma units monitor true power or insulation resistance. With an integrated display and menu-based configuration via rotary switches, PMDsigma guarantees short set-up and commissioning times.

PMDsrangeThese units are 22.5 mm wide and monitor functions such as current, voltage, temperature and many more.

Stand-alone machines with up to three safety functions, such as E-STOPs, safety gates, light curtains/grids and many more are monitored using the safety relays PNOZ. Every day they are proven in millions of applications worldwide. Due to the different features, the safety relays are divided into the following product ranges.

PNOZsigmaWith particularly narrow housing widths and multifunctionality compressed into each unit, PNOZsigma provides maximum functionality in minimum width. Selectable operating modes and times, plus scalability thanks to the modular structure, are further benefits.

Configurable control systems

PNOZeIog

PNOZ X

PNOZpower

PNOZmulti Mini

PNOZmulti

PNOZelog units can be linked via logic operations to form complete safety functions. Wear resistance and expanded diagnostics with power-up tests, self-checking and runtime tests guarantee maximum safety.

PNOZ XWith the widest range of products, PNOZ X provides tailor-made safety for any application. Based technically on voltage-free, electromech-anical contacts, widths vary from 22.5 to 90 mm, while the number of contacts ranges from 2 to 8. Universal power supplies are an added convenience for your application.

PNOZpowerPNOZpower switches high loads of 8-16 A and is also suitable for switching motor loads directly.

PNOZmulti Mini is a scalable product range, offering both stand-alone and system solutions. All functions are created on the PC using the ingeniously simple configuration software PNOZmulti Configurator. Inputs and outputs are freely configurable and can be linked using logic elements. With a 45 mm width and simple diagnostics via display, applica-tion of the PNOZmulti is cost-effective from just three safety functions. There are three base units: A compact, modular non-expand-able, stand-alone unit with 20 safe inputs and 4 safe semiconductor outputs. Other base units can be expanded using communication modules and safe link modules, enabling interlinked and decen-tralised plants to be implemented.

PNOZmulti bridges the gap between classic safety relays and programmable control systems. PNOZmulti can be used to monitor safety functions safely and to perform standard control functions economically. PNOZmulti is multifunctional and can be configured using the software tool PNOZmulti Configurator. It has a wide range of base units and expansion modules, which can be com-bined to meet individual require-ments: there are special base units for press applications or burner management, as well as input, output, fieldbus and link modules, as well as speed and standstill monitors. Use of PNOZmulti is economical where four or more safety functions are to be monitored.

Configuration software

Compact programmable control systems

Modular programmable control systems

PSS 3075

PSS 3047

PSS 3000

The safety circuit is created on the PC using configuration software that is simply ingeni-ous, yet ingeniously simple. The graphics-based user inter-face conforms to the Windows® standard; all elements are avail-able as icons or in selection menus. Online help with docu-mentation is available during configuration. Once the configu-ration is complete, the configu-ration tool checks the circuit for any errors. The completed con-figuration can also be certified, thereby protecting it from un-wanted modifications. If the configuration has not been certified, it can be edited, modi-fied and extended at any time by calling it up in the Configurator. The configuration can be printed out and used as documentation.

The control systems PSScompact exercise complete safety-related control of a plant, machine or process. Safe and powerful. Six series open the way to numerous application options - from centralised control systems with 47 failsafe inputs and outputs through to decen-tralised control systems with up to 8,064 decentralised, failsafe inputs and outputs via SafetyBUS p. Decentralised input/output signals can be exchanged quickly, safely and without feedback between field level and the control systems via SafetyBUS p interfaces.

Modular programmable control systems monitor safety-related functions and also perform standard control tasks. Thanks to the modular hardware struc-ture, the necessary hardware components can simply be assembled to fit the individual project requirements. Available hardware components include module racks, CPU central processing units, digital and analogue input/output modules as well as communication modules for all common fieldbuses and Ethernet.

Decentralised periphery

System software

PSSuniversal

PDP67

The hardware and software for Pilz decentralised periphery offer the highest level of flexibility. Decentralised I/O systems and a wide range of I/O modules enable a variety of combinations, allowing the most diverse applica-tions to be implemented.

Decentralised I/O system PSSuniversalThe decentralised I/O system PSSuniversal is available for a variety of applications. The open system includes head modules with interfaces to common field-bus systems and a wide range of I/O modules. Safety-related and standard control functions are mixed physically but are logically separated from each other - thereby fulfilling the requirements for extremely short reaction times and absence of feedback. The system is designed completely in accordance with Cat. 4 of EN 954-1 and SIL CL 3 of IEC 61508.

These modules are resistant to dirt and water in accordance with IP67. They can be used decentrally in the field (outside the control cabinet). Decentralised input modules are available for SafetyBUS p and for connection to PNOZmulti/ PNOZmulti Mini, as well as passive junctions, enabling a high level of decentralisation.

With various network compo-nents for safe fieldbus, Ethernet and wireless systems in com-bination with the I/O system PSSuniversal and control systems, networks can now be implemented with even greater clarity and higher performance.

Practical software solutions are available when designing and programming PSS control sys-tems - providing support from planning to diagnostics. Over 100 software function blocks make it easier to implement safety-related and/or standard control functions in the user software. The decentralised I/O system PSSuniversal can be configured using the Startup Software and PSSuniversal Assistant. Save time by running an independent periphery test prior to commis-sioning, for example.

Automation system PSS 4000

Systems

Control systems

TM

The automation system PSS 4000 consists of various hardware and software compo-nents, plus the real-time Ethernet SafetyNET p and corresponding network compo-nents. They are closely compatible, providing the solution for your automation project.Network components

Software platform

PSSuniversal PLC

PSSnet SHL

PSSnet SLL

Control systems PSSuniversal PLC

The control systems PSSuniversal PLC are the optimum solution for individual machines or complex, distributed plants - whether networked or stand-alone, for standard and safety applications. The systems can be programmed with PAS IL (Instruction List). A graphics Program Editor is also available for configuration.

Network components PSSnet for SafetyNET p

Ethernet infrastructure compo-nents PSSnet can be used to adapt the network topology flexibly to your plant layout. These components enable topologies such as star, tree and ring structure. Thanks to the use of various media such as fibre optics, network limits can now be expanded without problem.

Editors PAS IL and PASmulti

Programs can be created simply, quickly and intuitively using the graphics Program Editor PASmulti. Inputs and outputs can be freely configured and linked using logic elements. Simple structuring is also possible without difficulty. The Editor PAS IL (in accordance with EN/IEC 61131-3) can be used to create more complex programming for standard and safety. Both editors use the same software environment. A large library of software blocks is also available, aiding reusability and standardisation.

Decentralised system

Decentralised system PSSuniversal I/O

The decentralised system PSSuniversal I/O is responsible for recording and forwarding I/O data. A large number of standard and failsafe I/O modules guarantees diversity of application and security of investment.

Electronic modules

I/O modules

I/O modules are available for functional safety and standard control functions. Up to 64 modules can be installed in any order.

Drive technology

Components

Motion control systems

Pilz drive tech-nology provides overall solutions for automating your machine, from operation via the controller through to the movement of highly dynamic drives, including all safety aspects.

Servo amplifiers

Motors

PMCprimo

PMCtendo DD

PMCprotego D

PMCtendo

Control systems PMCprimo

PMCprimo 16+ and PMCprimo Drive are used for all types of motion and control tasks. They consist of PLC and motion technology. They perform the automation within a plant, including management of all the movements for a large number of physically separate servo axes.

Webcode 2314

Servo amplifiers PMCtendo DD and PMCprotego D

PMCtendo DD and PMCprotego D are suitable as drive controllers for the widest range of motor technologies: they can be used to operate all common types of motor, from servo motors to asynchronous and linear motors.

Webcode 2584

Servo motors PMCtendo AC

The PMCtendo AC range of motors can provide the right motor to meet your require-ments, whether the focus is on dimensions, dynamics, controllability, connection types or feedback systems.

Webcode 2597

Safe motion - Drive integrated safety

PMCprotego DS

PMCprotego DS

The combination of the safety card PMCprotego S and the servo amplifier PMCprotego D produces the safe drive solution safe motion. Safe functions help to reduce setup times and maintenance work and increase productivity.

Safe torque off (STO)

Safe stop 1 (SS1)

Safe stop 2 (SS2)

Safe operating stop (SOS)

Safely limited speed (SLS)

Safe speed range (SSR)

Safe direction (SDI)

Safe brake control (SBC)

Safe brake test (SBT)

Webcode 4549

Components

Operator and visualisation systems

As a solution supplier Pilz offers products from the fields of sensor, control and drive tech-nology. Why not add products from the field of operator and visualisation systems? That way you benefit from co-ordinated one-stop solutions.

Control and signal devices

Operator terminals

PITestop

PITsign

PITjog

PITenable

PITmode

PMImicro diag

PIT control and signal devices

Selection of the correct control/ signal device is a key factor for the safety of man and machine. Rely on a safe solution with Pilz E-STOP pushbuttons, muting lamps and manually operated control devices.

E-STOP pushbutton PlTestop

The E-STOP pushbuttons have a practical, industrial design and ensure safety for man and machine on emergency off/ emergency stop equipment.

Muting lamps PlTsign

Muting lamps PlTsign indicate that an electrosensitive protec-tive device is suspended. They are suitable for all muting applications in accordance with IEC 61496-1.

Manually operated control devices PlTjog

The manually operated control devices PlTjog are used to protect personnel when the effect of safety equipment on machinery has to be partially or fully overridden.

Enabling switch PlTenable

The three-stage enabling switches PlTenable are used as manually operated control devices when working in a plant or machine's danger zone.

Operating mode selector switch PlTmode

The operating mode selector switch PlTmode provides two functions in one compact unit: selection of operating mode and authorisation control for machine access.

Webcode 1474

Operator terminals PMI

Pilz offers the most diverse range of systems to perform diagnostic and visualisation tasks. So it's easy to implement customised, complete solutions that meet your requirement.

Diagnostic units PMlmicro diag

Compact diagnostic units PMlmicro diag for the program-mable control systems PSS, the safe bus system SafetyBUS p and the configurable control systems PNOZmulti.

Operator terminals PMlvisu/PMlopen

With the operator terminals PMIvisu/PMlopen you have modern touchscreen terminals in different sizes and with various feature options.

Webcode 0391

Services

Consulting and engineering

As a solution supplier, Pilz can help you to apply optimum safety strategies world-wide. Services encompass the whole machine lifecycle. Our training package with practical, up-to-date course content completes the offering.

Your projects belong in safe hands

Risk assessment

We will work with you to under-take a technical inspection of your machines in accordance with the applicable national and/or international standards and directives. The aim of this risk assessment is to identify and assess existing hazards in the workplace and define risk reduction measures.

Webcode 1081

Safety concept

Based on the results of the risk assessment, Pilz presents de-tailed technical solutions which guarantee plant safety through state-of-the-art mechanical, electrical and organisational measures, in compliance with national and international standards.

Webcode 0684

Safety design

Whether you are constructing new machinery or retrofitting existing machines - it is better to integrate a safe design right at the start of the project. Only a safety design that addresses the hazards can be implemented with minimum impact on the machine's complexity, costs and productivity.

Webcode 3314

International compliance services

Pilz will work with your engi-neers to carry out the required assessment procedures and develop the necessary strategies to enable compliance with the respective ISO, IEC and ANSI standards or any other stand-ards. This includes interpretation of the requirements for CE certification.

Webcode 3319

Plant assessment

The plant assessment includes an on-site inspection followed by evaluation and presentation of the results. Pilz will work with you to analyse the machine's workflow. The documented results can be used for machine optimisation.

Webcode 1080

Inspection of ESPE

As a DAkkS accredited in-spection body in accordance with DIN EN ISO 17020, with experience of the industry and technical competence, Pilz can guarantee objectivity, high availability for your machinery and the greatest possible safety for your staff.

Webcode 3314

System implementation

Based on the results from the risk assessment and safety design, experienced Pilz engineers can quickly implement the selected safety measures. Installation is carried out in compliance with regulations and standards, at minimum cost and with minimum downtimes.

Webcode 3296

Safety validation

The safety validation must show that the solutions that have been developed meet the actual requirements. This is done by mirroring the risk assessment and safety concept. Competent, specialist staff from Pilz can guarantee an objective and systematic procedure. The PAScal calculation tool helps you with verification.

Webcode 3297

CE services

The CE mark indicates that the marked machines meet the essential requirements of all the relevant EU directives. Pilz carries out all the actions and processes for CE certification and produces the necessary compliance strategies, safety designs and documents. That way your machine has a "passport" into the EU.

Webcode 0865

Business activties Components-Systems-Services

Safety gate systems PSENsgate - The integrated Pilz system

Safety light curtains and light grids PSEBopt

Convenient speed monitoring - Speed monitor PNOZ s30

Configurable safety relay PNOZmulti Mini - The development continues!

Configurable control system PNOZmulti width Ethernet interface

Decentralised input module - PDP67 F 8DI ION

Passive junction -PDP67 F 4 code

PSSuniversal - Safe analogue inputs now also decentralised

PSSuniversal - Safe speed, safe position

PSSuniversal - Fast, local switching functions guaranteed

PSSuniversal also communicates via PROFINET/PROFIsafe

PSS4000 - safe rotary cam arrangement

For mode selection and access authorisation - Operating mode selector switch PITmode

Pilz is a leading, innovative automation technology company.

As experts in the safety of human, machine and the environment, Pilz provides worldwide, customer-oriented solutions for all industries.

These include innovative products and comprehensive services from the areas of sensor, control and drive technology.

Not every leaflet may be available in the language you require. If this is the case, please select a different language.

To open a leaflet, please double-click on the relevant front cover.

Sensor technology PSEN

Relays for functional safety PNOZ, configurable control system PNOZmulti

PSS Programmable Safety and Control Systems

Drive technology PMC

Control and signal devices PIT

PMI operator terminals

Industrial Automation

PSS 4000 -safe electronic camshaft

PSENvip + PSS 4000 = highest productivity for press brakes

Safety Services

Pilz training -Machinery safety seminars

All in one: Safety gates systems PSENsgate combine safety gate monitoring, safe guard locking and broken bolt monitoring all in one system. As a result, PSENsgate can be used in applications up to PL e of EN ISO 13849-1, SIL CL 3 of EN/IEC 62061 and Category. 4 of EN 954-1. Safety gate systems PSENsgate are particularly suitable for classic, large safety gates and for safety gates which must not be opened unintentionally.

All the safety functions for monitoring safety gates (emergency stop and auxiliary/escape release) plus all control elements are integrated within the smallest space. In conjunction with Pilz control technology, they form the safe, complete solution for safety gate protection.

Combined electro-mechanical system enables the highest category with just one switch per safety gate: protection of personnel and plant

Reduced installation and wiring effort due to integrated control elements and the ability for series connection

Unit width of 45 mm, suitable for 45 mm profiles

Diagnostics enable fast reaction times to status changes

Integrated emergency stop removes the need for an evaluation device and expansion modules

Safe, complete solution when combined with Pilz control technology

Mechanical data |

|

|

► Holding force, swing gate |

2000 N |

|

► Holding force, bolt (holding pin) |

1000 N |

|

► Lateral/ vertical offset |

+1-5 mm and |

|

► Connection type |

+/-5 mm respectively Plug-in spring-loaded terminals |

Electrical data |

|

|

► Power consumption depends on configuration (gate locked) |

Max. 2 W |

|

► Supply voltage |

24V |

|

► Voltage tolerance |

15/+10% |

|

► Safety outputs 2 (semiconductor, max. 500 mA each) |

2 |

|

► "Safe range" input(solenoid pin) |

1.5A, 150ms |

|

► Signal output |

500mA |

Series connection |

|

|

► In combination with PSENslock, PSENsgate, PSENcode |

Up to PL e, SIL CL 3 |

Protection class |

|

|

► IP65 (unit) |

|

|

► IP54 (wiring space) |

|

Dimensions PSEN sglc-1/2 in mm (H x W x D) |

|

|

► 466 x 200 x 104.5 |

|

Dimensions PSEN sglc-4/1 in mm (H x W x D) |

|

|

► 556 x 200 x 104.5 |

|

► PSEN sgl c-2/1 2 pushbuttons and emergency stop device1) |

570700 |

|

► PSEN sgl c-4/1 4 pushbuttons and emergency stop device2) |

570701 |

Use safe PSENopt light curtains and light grids to safeguard danger points and danger zones in which the production process requires active intervention. PSENopt provides finger and hand protection in accordance with EN/IEC 61496-1/-2. The new PSENopt light grids are an effective and cost-saving alternative to conventional mechanical guards when workflows require operators to encroach into the danger zone or with automatic material flow.

Combined with the control technology from Pilz, you receive a safe, complete solution.

Ergonomic workstation design in comparison to mechanical guards

Maximum safety, as they are tested and approved in accordance with EN/IEC 61496-1/-2

Operating range up to 19 m

Reduced response times

Rapid installation and simple maintenance by means of simple connection technology, functional fastening system and ready-made cables

Simple commissioning and economical operation due to - compact dimensions - integrated alignment guide - built-in diagnostic function - rotating brackets

|

► Safe outputs |

2 |

|

► Resolution |

Finger (14 mm) |

|

Hand (30 mm) |

|

|

► Approved in acc. with EN/IEC 61496-1/2 |

Type 2/Type 4 |

|

► Functions/features |

Test/reset |

|

► Height of protected field |

150 ... 1800 mm |

|

► Operating range |

PSEN op2H: 0.2 ... 19 m |

|

PSEN op4H: 0.2 ... 19 m |

|

|

PSEN op4F: 0.2 ... 6 m |

|

|

► Light grid reaction time |

PSEN op2H: 8 ... 24 ms |

|

|

PSEN op4F: 11 ... 50 ms |

|

|

PSEN op4H: 9 ... 28 ms |

|

Type |

Height of |

Reaction |

Finger |

Hand |

|

protected field |

time |

protection |

protection |

|

Type 2 H acc. to EN/IEC 61496-1/-2 |

||||

|

► PSEN op2H-s-30-015/1 |

150 mm |

8 ms |

- |

630720 |

|

► PSEN op2H-s-30-030/1 |

300 mm |

9 ms |

- |

630721 |

|

► PSEN op2H-s-30-045/1 |

450 mm |

11 ms |

- |

630722 |

|

► PSEN op2H-s-30-060/1 |

600 mm |

12 ms |

- |

630723 |

|

► PSEN op2H-s-30-075/1 |

750 mm |

14 ms |

- |

630724 |

|

► PSEN op2H-s-30-090/1 |

900 mm |

15 ms |

- |

630725 |

|

► PSEN op2H-s-30-105/1 |

1050 mm |

17 ms |

- |

630726 |

|

► PSEN op2H-s-30-120/1 |

1200 mm |

18 ms |

- |

630727 |

|

► PSEN op2H-s-30-135/1 |

1350 mm |

20 ms |

- |

630728 |

|

► PSEN op2H-s-30-150/1 |

1500 mm |

21 ms |

- |

630729 |

|

► PSEN op2H-s-30-165/1 |

1650 mm |

23 ms |

- |

630730 |

|

► PSEN op2H-s-30-180/1 |

1800 mm |

24 ms |

- |

630731 |

Type 4 F acc. to EN/IEC 61496-1/-2 |

||||

|

► PSEN op4F-s-14-015/1 |

150 mm |

11 ms |

630740 |

- |

|

► PSEN op4F-s-14-030/1 |

300 mm |

15 ms |

630741 |

- |

|

► PSEN op4F-s-14-045/1 |

450 mm |

18 ms |

630742 |

- |

|

► PSEN op4F-s-14-060/1 |

600 mm |

22 ms |

630743 |

- |

|

► PSEN op4F-s-14-075/1 |

750 mm |

25 ms |

630744 |

- |

|

► PSEN op4F-s-14-090/1 |

900 mm |

29 ms |

630745 |

- |

|

► PSEN op4F-s-14-105/1 |

1050 mm |

33 ms |

630746 |

- |

|

► PSEN op4F-s-14-120/1 1 |

200 mm |

36 ms |

630747 |

- |

|

► PSEN op4F-s-14-135/1 |

1350 mm |

40 ms |

630748 |

- |

|

► PSEN op4F-s-14-150/1 1 |

500 mm |

43 ms |

630749 |

- |

|

► PSEN op4F-s-14-165/1 1 |

650 mm |

47 ms |

630750 |

- |

|

► PSEN op4F-s-14-180/1 1 |

800 mm |

50 ms |

630751 |

- |

Type 4 H acc. to EN/IEC 61496-1/-2 |

||||

|

► PSEN op4H-s-30-015/1 |

150 mm |

9 ms |

- |

630760 |

|

► PSEN op4H-s-30-030/1 |

300 mm |

11 ms |

- |

630761 |

|

► PSEN op4H-s-30-045/1 |

450 mm |

13 ms |

- |

630762 |

|

► PSEN op4H-s-30-060/1 |

600 mm |

14 ms |

- |

630763 |

|

► PSEN op4H-s-30-075/1 |

750 mm |

16 ms |

- |

630 764 |

|

► PSEN op4H-s-30-090/1 |

900 mm |

18 ms |

- |

630765 |

|

► PSEN op4H-s-30-105/1 |

1050 mm |

19 ms |

- |

630766 |

|

► PSEN op4H-s-30-120/1 |

1200 mm |

21 ms |

- |

630767 |

|

► PSEN op4H-s-30-135/1 |

1350 mm |

23 ms |

- |

630768 |

|

► PSEN op4H-s-30-150/1 |

1500 mm |

25 ms |

- |

630 769 |

|

► PSEN op4H-s-30-165/1 1 |

650 mm |

26 ms |

- |

630770 |

|

► PSEN op4H-s-30-180/1 |

1800 mm |

28 ms |

- |

630771 |

As the new Machinery Directive becomes valid, a new requirement in the field of drive monitoring comes to the fore: When the drive is brought to a standstill, the operating status must be safely monitored and maintained. Pilz already provides options for safe speed monitoring. Drive-integrated safety with the PMCprotego DS and external drive monitoring with the PNOZmulti speed module. And now there's the new speed monitor PNOZ s30, which provides safe monitoring of standstill, speed and direction of rotation. So the right speed monitoring solution is available for each application.

Increased productivity and safety for operating personnel thanks to safe monitoring of standstill, speed and direction of rotation

Save time during setup and when units are exchanged, thanks to convenient operation via rotary knob (push and turn)

Save time during commissioning and when units are exchanged, as parameters are saved on to chip card

Productivity is increased by avoiding unnecessary shutdown processes: advance warning is given when a defined warning threshold is reached

Suitable for all common motor feedback systems and proximity switches

Parameters for device functions such as standstill can be freely set and assigned to an output

Parameters are entered via rotary knob (push and turn) in conjunction with a monochrome display

Set parameters are saved on a chip card

Integrated display shows the set limit values/ parameters as well as the current speed

Tolerances can be freely set for each limit value

Optional axis position monitoring is available with the standstill function

Advance warning of shutdown when a certain threshold is reached

2 N/O and 2 N/C as output contacts

24 ... 240 VAC/DC

Performance Level (PL) in accordance with EN ISO 13849-1, PL e

Safety Integrity Level (SIL), CL claim limit in accordance with IEC 62061, SIL CL 3

Category in accordance with EN 954-1, Cat. 3

100/98" x 45 x 120 *Height with spring-loaded terminals/plug-in screw terminals

|

► PNOZ s30 (with plug-in screw terminals) |

750330 |

|

► PNOZ s30 (with spring-loaded terminals) |

751330 |

Following on from the configurable safety relay PNOZ mm0p, which now has configurable inputs/outputs and displays individual customer texts, comes the PNOZ mm0.1 p! The configurable safety relay PNOZ mm0.1 p can be expanded to the left and right and also enables sensor technology to be connected in series via the decentralised input module PDP67 F 8DI ION.

Configurable inputs and outputs

Simple diagnostics through integrated display with customised text

Configuration rather than wiring with the proven "PNOZmulti Configurator"

PVIS support

Save up to 40 % of time and costs in all engineering phases

Less wiring, saves a lot of space in the control cabinet

Can be expanded to the left and right via link modules

Decentralisation: sensor technology can be connected outside the control cabinet via the PDP67 F 8DI ION

Configurable using PNOZmulti Configurator via chip card or USB interface

Exchangeable program memory

20 inputs

safe semiconductor outputs (SIL CL 3)

4 test pulse outputs

Supply voltage (UB): 24 VDC

Voltage/current/rating: - Outputs using semiconductor technology: 24 VDC/2 A/48 W

Expandable - To the left with link modules PNOZ mml1 p, PNOZ mml2p and the communication module PNOZ mmc1 p (Ethernet TCP/IP) - To the right with PNOZ s7 to PNOZ s11 and PNOZ s12

Decentralisation - Sensor technology can be connected via the PDP67 F 8DI ION

PNOZ mm0.1 p is tested and approved in accordance with all relevant standards:

EN ISO 13849-1

EN/IEC 62061

EN/IEC 61508-1 to 4

EN 60204-1

EN/IEC 61511 part 1-3

IEC 61131-2

UL 508

UL 1998

NFPA 79

100 x 45 x 120

|

► PNOZ mm0.1p (excl. terminals) |

772001 |

|

► 1 set of spring-loaded terminals |

751008 |

|

1 set of plug-in screw terminals |

750008 |

|

Mini USB cable: |

|

|

► 3 metres |

312992 |

|

► 5 metres |

312993 |

The Pilz safety system PNOZmulti is multifunctional, freely configurable and tailor-made for use in many areas of engineering. PNOZmulti can be used to monitor safety functions safely and perform standard control functions economically. All the necessary functions are created on the PC with ingeniously simple configuration software. PNOZmulti: many functions - one solution!

New: Pilz can now offer the PNOZmulti with an Ethernet interface, so it fits in with the ongoing development of the industrial communication networks.

Save time thanks to remote maintenance

Enables preventive maintenance

Integrated switch

TCP/IP interface for: - Downloading the project - Reading the diagnostic data - Setting virtual inputs for standard functions - Reading virtual outputs for standard functions

-8 expansion modules on the right

-1 fieldbus module on the left

-4 expansion modules on the left

The RJ45 interfaces on the internal autosensing switch enable process data to be exchanged with other Ethernet subscribers within a network.

The PNOZ m1p ETH can also be connected to Ethernet via a hub (hub or switch).

The digital input module PDP67 F 8DI ION monitors safety functions decentrally in the field - and as such is the first safety-related IP67 module that can be connected to a variety of evaluation devices, such as PNOZmulti, PNOZmulti Mini and in future PSS 4000!

Direct on-site installation through a simple screw assembly minimises your planning, design and installation work - saving you time, money and space in the control cabinet! Communication with the configurable control system PNOZmulti is via a safe data link.

Simpler than a fieldbus system (no bus terminating resistor, no separate address)

Simple installation means less planning, design and installation work

No control cabinet necessary

Modular machine concept is possible

One cable for communication and supply

Configuration is simple with the proven PNOZmulti Configurator

One module for PNOZmulti, PNOZmulti Mini and in future PSS 4000

Incorporated into ingenious IP67 housing, the passive junction PDP67 F 4 code optimises installation and wiring effort by removing the need for additional, cost-intensive hardware, such as a control cabinet for example.

Now you can connect up to 4 PSENcode to any evaluation device (PNOZ X, PNOZsigma, PNOZmulti etc.) via a single PDP67 F 4 code, using proven M12 connection technology.

Simple installation means less planning, design and installation work

No control cabinet necessary

Modular machine concept is possible

One cable for communication and supply

Possible to connect to any evaluation device

Can be cascaded using T-Junction and Y-Junction

In the automation system PSS 4000, safe analogue input modules are now available for the control systems PSSuniversal PLC and PSSuniversal I/O. They can be used to implement applications that require safe, decentralised recording of analogue values.

Reduced installation effort due to short cable routes, thanks to decentralised, safe recording of analogue values

Interference on measuring lines is minimised and shielding measures are reduced

Reduced space requirement in the control cabinet due to narrow design

The various periphery modules can be adjusted flexibly thanks to the system's fine granularity

For use in the automation system PSS 4000

Valve position monitoring on process machinery

Monitoring semiconductor processes

Lamp monitoring on traffic signalling systems (e.g. level crossings)

Controlling multi-stage burners in burner management

...

In the automation system PSS 4000, safe counter modules are now available for the control system PSSuniversal PLC. Applications can be implemented safely by combining a counter module with special function blocks in the user program, standard encoders and approval from a certified body.

Safe evaluation of speed, position and standstill using standard rotary encoders

The safe monitoring function is transferred to the user software

Greater flexibility when monitoring limit values due to dynamic limit value monitoring in the user program

Universal usability and expandability due to standardised interfaces, irrespective of the encoder type and manufacturer

For use in the automation system PSS 4000

The modules PSSu E F ABS SSI and PSSu E F INC record the counter statuses. The software blocks evaluate these and use the information to calculate the position.

The safe software block FS_CounterDual is used for safe evaluation of two counter signals. This way, safe position, speed and standstill 1) can be monitored using existing standard encoders.

With the new standard counter module PSSu E S INC 24V se it is now possible to read 24 V counter signals in the decentralised I/O system PSSuniversal. The module is used when 24 V incremental encoders or initiators/proximity switches are used. It has a local switch output, which is activated as soon as the counter value has reached a preset value.

Shorter switching and reaction times, as there is no need to consider program processing and transfer times via internal or external communication interfaces

User program is independent, as the switch function is encapsulated directly within the I/O module

Cost of the application is reduced by saving on an interface converter

In addition to the new counter module, electronic modules with serial interface (RS232 interface; RS485 interface) are also now available.

Easily perform safety-related and/or standard control functions decentrally at field level with the decentralised I/O system PSSuniversal. Communication with the control system is via PROFINET/PROFIsafe.

Now PROFINET users can also enjoy the benefits of the decentralised I/O system PSSuniversal: high level of safety, integrated standard automation, absence of feedback between standard and safety, modular system structure, rapid commissioning with the PSSuniversal Startup Software. Its possible to save up to 40 % of power dissipation - compared with other systems - depending on the number of safe modules required.

The PROFIsafe address is only required once perdecentralised station, i.e. safety settings for each device are made at a single point

Simple operation; no need for address setting and address management on each individual I/O module

Optimum utilisation of FS addresses and the number of addresses; less work involved in planning and management

Easier orientation within the system thanks to half byte mapping

Called up via TCI

Configures the system

Generates station-specific GSDML files

Manages all the safety-related CRC sums

The operating mode selector switch PlTmode provides two functions in one compact unit: selection of operating mode and authorisation control for machine access. As an operating mode selector switch it enables you to switch between defined operating modes. That way, each operator is given the machine enables that match his abilities. Thanks to identification management it is possible to assign authorisations in the machine control system that influence the access authorisations in the PlTmode operation. The PITmode can be used on plant and machinery in which a range of control sequences and operating modes are used.

The evaluation device safely identifies and evaluates the selected operating mode

Saves space, as operating mode selector switch and access authorisation are combined in one unit

Long service life thanks to non-contact principle (maintenance-free and non-wearing)

High level of safety, as manipulation protection is increased through universal coding

Saves time because there is less administration work; several mechanical keys are combined within one transponder key

Safe proximity switches

Safe proximity switches Safe rope pull switches

Safe rope pull switches Safety bolts

Safety bolts Safe hinge switches

Safe hinge switches Safety gate systems

Safety gate systems Safety light beams/curtains/grids

Safety light beams/curtains/grids Camera-based protection and measring systems

Camera-based protection and measring systems Safe camera systems

Safe camera systems

Relays for electrical safety

Relays for electrical safety Relaysfor functional safety

Relaysfor functional safety Configurable control systems

Configurable control systems Compact programmable control systems

Compact programmable control systems Decentralized periphery

Decentralized periphery

Network components

Network components Industrial communication

Industrial communication

Motion control systems

Motion control systems Servo amplifiers

Servo amplifiers Motors

Motors

Control and signal devices

Control and signal devices Operator terminals

Operator terminals

System software and tools

System software and tools Application software

Application software

Control systems

Control systems Real-time Ethernet

Real-time Ethernet Software platform

Software platform

Risk Assessment

Risk Assessment Safety Concept

Safety Concept Safety Design

Safety Design System lmplementation

System lmplementation Safety Validation

Safety Validation

Seminars

Seminars Courses

Courses

Pilz product areas................................................

Pilz product areas................................................

|

4 |

Sensor technology product area..........................

Sensor technology product area..........................

|

6 |

Product group: safe proximity switches.................

Product group: safe proximity switches.................

|

|

| - Safe proximity switches PSENini............................. | 8 |

Product group: safe rope pull switches

Product group: safe rope pull switches

|

|

|

|

10 |

Product group: safety switches,

Product group: safety switches,safety bolts and safe hinge switches...................................... |

12 |

| - Mechanical safety switches PSENmech................... | 14 |

|

- Non-contact,magnetic safety switches PSENmag........................................ |

18 |

|

-Non-contact, coded safety switches PSECcode...................................... |

24 |

| -Safety bolts PSENbolt............................................. | 28 |

| -Safe hinge switches PSENhinge............................... | 30 |

Product group: safety gate systems....................................

Product group: safety gate systems....................................

|

32 |

| -Safety gate systems PSENslock............................... | 34 |

| -Safety gate systems PSENsgate............................... | 36 |

Product group: safety light beams,

Product group: safety light beams,curtains and grids.............................................. |

40 |

|

- Safety light beams, curtains and grids with semiconductor outputs - PSENopt........................ |

42 |

|

-Light curtains and grids with integral SafetyBUS p interface - PSENopt SB......................... |

50 |

Product group: Camera-based protection and

Product group: Camera-based protection andmeasuring systems. |

|

|

-Camera-based protection and measuring systems PSENvip....................................... |

52 |

Product group: safe camera systems

Product group: safe camera systems

|

|

| -Safe camera systems SafetyEYE.............................. | 56 |

Compatible with sensor technology:

Compatible with sensor technology:Control technology and services................................................ |

62 |

Sensor technology and accessories......................................

Sensor technology and accessories......................................

|

64 |

Pilz offers a universal concept for solutions that can be applied right across industry. Whether you need a single product or a total solution: with Pilz you will definitely find a solution for your automation function.

A ready-to-install system offers high potential savings in project configuration, design, documentation, purchasing and installation.

Enjoy the benefits of approved, coordinated, complete solutions, such as sensor plus control technology from Pilz. That's the only way to save time and money in the implementation of all components, including certified safety.

The optimum solution for every requirement

Out comprehensive product range covers the whole spectrum of safety requirements. Just assemble your own individual system solution, selecting the safety-related components that best suit your requirements.

Control technology

Solution suppliers for safety and standard

Out sensor technology portfolio is supplemented by control technology, drive technology, operator and visualization systems, plus software.

Quality guarantee plus certified safety

Pilz is certified to EN ISO 9001. Our product comply with inter-national standards and have been tested and approved by international certification bodies.

Services from the safety professionals

Pilz is there beside you, acting as your competent partner during all phases of the machine's life: from the risk assessment and production of safety concepts through to implementation and validation. We can also offer CE-marking and other compliance services.

Keep up-to-date on:

Products

Products

webcode 0326

webcode 0326

Services

Services

webcode 0427

webcode 0427

Dialong with Pilz:

Page 72

Page 72

Webcode 0627

Webcode 0627

Online information at www.pilz.com

The best solution for every requirement

When the protection of man, machine and the environment is at stake in an industrial scenario, plants need to be efficient: from commissioning right through to higt availability when operation is running. Here Pilz can offer a safe, complete, one-stop solution.

Free choice- for your application

Our components for both sensor and control technology are totally compatible and have been approved as a safe, overall system. For your tailor-made solution, just select the appropriate safe sensors:

Proximity switches-

Proximity switches-

from page 8

Rope full switches-

Rope full switches-

from page 10

Switches -from page 12

Switches -from page 12

Bolts(incl.safety switches)-

Bolts(incl.safety switches)-

from page 28

Hinge switches-

Hinge switches-

from page 30

Safety gate systems-

Safety gate systems-

from page 32

Light beams/curtains/grids-

Light beams/curtains/grids-

from page 40

Camera-based protection

Camera-based protection

and measuring systems-

from page 52

Camera systems-

Camera systems-

from page 56

Protection for your investment

Our product are also compatible with products and interfaces from other manufacturers. They fit perfectly into your plant environment and also enable Pilz components to be retrofitted to your plant or machine.

We place great value on per-formance, robustenss, quality and ease of operation. With PSEN sensers, your investments are assured over many years because out systems are flexible to adapt to new requirements and are constrantly undergoing development.

Keep up-to-date on:

Sensor

Sensor  webcode 0219

webcode 0219

Control

Control page 62

page 62

Webcode 0196

Webcode 0196

Online information at www.pilz.com

7

... safe monitoring without actuators

Safe proximity switches PSENini detect the approach of metallic objects without the use of con-tacts. They supply the necessary safe signals via positions and end limits.They can also the pulse for counting tasks or for speed detection.

Applications for PSENini:

Cam

Cam

Rolling doors

Rolling doors

Pulse generator for counting

Pulse generator for counting

tasks or detecting rotational

movements

High producttivity and long service life

Compared with mechanical switches, PSENini provide the ideal prerequisites for high pro-ductivity and a long service life: non-contact, non-wearing frequen-cies and switching precision.

They are also insensitive to vibration, shock and humidity.

high savings potential in series

Take advantage of the high savings potential of PSENini, even with the very highest safety requirements, because PSENini can also be connected in series with safety switches PSENcode and safety gate systems PSENslock and PSENsgate.

|

Product area Pilz SENsors |

Series | Connection type | ||

|

Product range in-PSENini |

1 Series 1 | p Connector, M12, 8-pin n Connector, M12, 5-pin |

||

|

Operation Non-contact, inductive |

The optimum solution: Position monitoring on the cam proximity switch PSENini and control system PNOZmulti.

Your benefits at a glance

The safe, complete solution:

The safe, complete solution:

we provide the appropriate

evaluation device for PSENini.

Protection for your investment:

PSENini are open to interfaces

from ather manufacturers and so

can easily be retrofitted into

your plant.

Protection for your investment:

PSENini are open to interfaces

from ather manufacturers and so

can easily be retrofitted into

your plant.

Good diagnostics via LEDs

Good diagnostics via LEDs

Scalable and flexible:

Scalable and flexible:

take advantage of the savings

potential from series connection,

even with the very highest safety

requirements

Simple project configuration,

Simple project configuration,

as the unit is highly versatile:

-Insensitive to shock and vibration

-With heavy soiling and strict

hygiene regulations (IP67)

| Type | Features |

|

PSEN in1p Order number: 545 000 |

|

|

PSEN in1n Order number: 545 003 |

Keep up-to-date on:

Sensor

Sensor  webcode 0219

webcode 0219

Control

Control page 62

page 62

Webcode 0196

Webcode 0196

Online information at www.pilz.com

9

... greater safety on the production line

Whether on the assembly line or machine - where sefety in the production area is concerned, safe rope pull switches PSENrope are a prowen, reliable solution.

PSENrope switch off functional processes through manual operation, PSENrope provide maximum safety when it matters: the emergency stop function can be triggered at any point along the rope.

Optimum safety solution is as simple as that

PSENrope are flexible to use, easy to install and simple to operate. Whether it's a first-time installation or ipgrades: safe rope pull switches PSENrope simplity installtion with their sophisti - cated technical details.

Durable - even under extreme conditions

As the operating range of rope pull switches is limited only by the length of the rope, even large plants can be safeguarded using PSENrope.

PSENrope provide a reliable service, even under extreme environmental conditions. This is mainly due to the rugged finish.

|

Product area Pilz SENsors |

Housing material | Contrcts | Max, spring force to tension the rope | |||

|

Product range rs-PSENrope |

1 Al die cast 2 Plastic |

0 2NC, 2 NO | 175 175N 300 300 N |

|||

|

Operation Non-contact, inductive |

The optimum solution: Repid emergrncy stop with rope pull switch PSENrope in conjunction with safe relay PNOZsigma.

Your benefits at a glance

High level of safety:

High level of safety:

-safe from manipulation

-Wiring space physically

separate from mechanics

-Dual function mushroom-

type pushbutton:

emergency stop and pull-

to-release

Whether it's a first-time

Whether it's a first-time

Installation or upgrade:

PSENrope simplify installation

Suitable for indoor and

Suitable for indoor and

outdoor use thanks to rugged,

hard-wearing metal or plastic

housing

| Type | Housing material | Maxximum rigging length | order number |

| PSEN rs1.0-300 | Al die cast | 75.0 m | 570300 |

| PSEN rs2.0-175 | Plastic | 37.5 m | 570303 |

| PSEN rs2.0-300 | Plastic | 75.0 m | 570302 |

| PSEN rs1.0-175 | Al die cast | 37.5 m | 570301 |

Soitable for applications up to:

Soitable for applications up to:

- PL e of EN ISO 13849-1

- SIL CL 3 of EN/IEC 62061

Category 4 of EN 954-1

(with additional measures)

Integrated emergency stop

pushbutton

Integrated emergency stop

pushbutton

Contacts: 2 NC, 2 NO

Contacts: 2 NC, 2 NO

Protection type: IP67

Protection type: IP67

Ambient temperature:

Ambient temperature:

PSEN rs1.0: -30...+80°C

PSEN rs2.0: -25...+70°C

Dimensions (H x W x D)

Dimensions (H x W x D)

PSEN rs1.0: 237 x 90.0 x 88 mm

PSEN rs2.0: 294 x 42.5 x 88 mm

Technical documentation on safe rope pull switches PSENrope:

Webcode 6000

Webcode 6000

Accessories, supplementary products and servives:

From page 62

From page 62

Webcode 0326

Webcode 0326

Online information at www.pilz.com

11

... for safety gate and position monitoring

Pilz safety gate components are particularly economical in meeting the requirements of EN 1088. They are suiable for applications in mechanical engineering as well as in the packaging or pharmaceutical indestry and many other sectors.

Safety switches - for safety gate and position monitoring at optimum cost

Safety switches are affective and optimized for cost. Thay are available with various designs and operating principles and can be used under difficult environmental conditions. Additional costs can be saved when connected in series.

Choose the optimum switch for your application:

Mechanical - using increased extraction

force on the actuator the PSENmech can

prevent the safety gates from being

opened unitentionally

Mechanical - using increased extraction

force on the actuator the PSENmech can

prevent the safety gates from being

opened unitentionally

Non-contact, magnetic - the magnetic

operation of the PSENmag is ideal for

applications with the highest safety

requirements

Non-contact, magnetic - the magnetic

operation of the PSENmag is ideal for

applications with the highest safety

requirements

Non-contact, coded - PSENcode offers

the highest level of safety and

manipulation protection with in integrated evaluation in the smallest

space possible

Non-contact, coded - PSENcode offers

the highest level of safety and

manipulation protection with in integrated evaluation in the smallest

space possible

Safety bolts - the robust, cost-effective solution for a rugged industrial environment

PSENbolt safety bolts are the ideal solution for safety gates that are difficult to adjust or are used in areas where safety gates are often opened and closed. What you get is a complete, economical package comprising safety switch, handle and bolt, for a rugged industrial environment.

Safe hinge switches - packaged hinge and safety switch

For hinged safeguards, safe hinge switchs PSENhinge are a safe complete solution, com-prising hinge and safety switch. Designed as one functional and installation unit, they offer a high level of flexibility in installation, connection and adjustment.

| Type | Safety switches PSENmech | Safety switches PSENmag | Safety switches PSENcode | Safety bolts PSENbolt | Hinge switches PSENhinge |

| Operation | Mechanical | Non-contact,magnetic | Non-contact,coded | Mechanical | Mechanical |

| Application on guards Covers | u | u | u | u | |

| Flaps | u | u | u | u | u |

| Hinged safety gates | u | u | u | u | u |

| Sliding safety gates | u | u | u | u | |

| Rolling doors | u | u | |||

| Position detection | u | u | |||

| Manipulation protection | Normal | Normal | High | High | High |

| Guard locking | With/without | None | None | With(2) | None |

| IP protection type | Up to IP65/IP67 | IP67/IP69K | IP67 | (3) | IP67 |

| Harsh environmental conditions | Suitable | Very suitable | Very suitable | Very suitable | Very suitable |

1)When using non-contact, coded safety switaches PSENcode

2)When using mechanical safety switches PSEN me 1 with guard locking

3) DEpending on the safety switch that is used.

Keep up-to-date on safety switches, safety bolts and safe hinge switches:

Webcode 0307

Webcode 0307

Online information at www.pilz.com

13

...and the gate stays closed

PSENmech mechanical safety switches are suitable for safe monitoring of a movable guard. They are triggered if the guards are opened and the hazardous machine movement is stopped via a Pilz evaluation device.

Guard locking until the risk is averted

Using increased extraction force on the actuator, PSENmech safety switches prevent the safety gate from being opened unintentionally. They comply with the standard EN 1088 (protection against defeat) due to their coded actuators.

PSENmech safety switches with guard locking ensure that the safety gate is interlocked (guard locking) until the hazardous production process is complete. They can also prevent production from being interrupted as a result of unauthorized access.

Product area Pilz SENsors

Product range me - PSENmech

Operation Mechenical

Product series

1 With guard locking,

demensions:

170 X 42.5 x 51 mm

2 Without guard locking,

dimensions:

75 X 52 x 33 mm

3 Without guard locking,

dimensions:

90 X 52 x 33 mm

4 Without guard locking,

dimensions:

100 X 31 x 30.5 mm

Series 1:

Inrerlock

princiole/supply voltage

S Spring force, 24 VAC/DC

.2S Spring force, 120, 230 VAC

M Megnetic force, 24 VAC/DC

Series 2: Contacts

- 1 NC

Series 3: Contacts

- 1 NC, 1 NO

.1 2 NC

.1 2 NC, 1 NO

Series 4: Contacts/extraction force

- 1 NC, 1 NO

.01 1 NC,1NO, 50 N extraction force

.1 2 NC

.11 2 NC, 50 N extraction force

.2 2 NC, 1 NO

.11 2 NC,1 NO, 50 N extraction force

Series/actuator type

1AS Standard, Seeries 1

1AR Radius, Series 1

2AS Standard,

Series 2 and 3

2AR Radius,

Series 2 and 3

4AS Standard,Series 4

The optimum solution: Monitoring sliding gates using the PSENmech safety switch and PNOZsigma safety relay.

Your benefits at a glance

Safe, complete solution in conjunction with

Pilz evaluation devices for applications with

high safety requirements

Safe, complete solution in conjunction with

Pilz evaluation devices for applications with

high safety requirements

Flexibility and saeed during installation

due to:

Flexibility and saeed during installation

due to: Long product service life due to the robust

design and high mechanical load capactity

Long product service life due to the robust

design and high mechanical load capactity

Suitable for a variety of applications due to the

wide operating temperature range

Suitable for a variety of applications due to the

wide operating temperature range

Housing is insensitive to dirt, dust-tight and

waterproof

Housing is insensitive to dirt, dust-tight and

waterproof

Universal actuation directions provide flexibity during installation.

Technical documentation on safe rope pull switches PSENrope:

Webcode 6000

Webcode 6000

Accessories, supplementary products and servives:

From page 62

From page 62

Webcode 0326

Webcode 0326

Online information at www.pilz.com

15

Common features

Safety switches for monitoring the

Safety switches for monitoring the

position of movable guards in

accordance with EN 60947-5-3

Suitable for applications

up to:

Suitable for applications

up to:

-PL e of EN ISO 13849-1

-SIL CL 3 of EN/IEC 62061

-Category 4 of EN 954-1

(with additional measures)

Can be connected to all

Can be connected to all

Pilz evaluation devices

Directions of actuation:

Directions of actuation:

-PSEN me1: eight

-PSEN me2: four

-PSEN me3: four

-PSEN me4: eight

Contact load PSEN me1:

Contact load PSEN me1:

-Utilization category:

AC-15: 230 V/2.5 A

-Conv. thermal current:

2.5 A

Dimensions

Dimensions

(HxWxD, excl, actuator)

-PSEN me1:

170 x 42.5 x 51 mm

-PSEN me2:

75 x 52 x 33 mm

-PSEN me3:

90 x 52 x 33 mm

-PSEN me4:

100 x 31 x 30.5 mm

Ambient temperature:

Ambient temperature:

-PSEN me1:

-25...+70°C/-13...+158F

-PSEN me2,me3, me4:

-30---+80°C/-22...+176F

Connection terminals:

Connection terminals:

-PSEN me1: Spring-loaded terminals

-PSEN me2, me3,me4: Screw terminals

Protection type

Protection type

-PSEN me1:IP67

-PSEN me2, me3, me4:IP65

Plastic-bordied design

Plastic-bordied design

| Type | Interlock principle |

| PSEN me1S/1AS | Spring force |

| PSEN me1.2S/1AS | Spring force |

| PSEN me1S/1AR | Spring force |

| PSEN me1.2S/1AR | Spring force |

| PSEN me1M/1AS | Magnetic powered |

| PSEN me1M/1AR | Magnetic powered |

| Type | Actuator type |

| PSEN me2/2AS | Standard |

| PSEN me2/2AR | Radius |

| PSEN me3/2AS | Standard |

| PSEN me3/2AR | Radius |

| PSEN me3.1/2AS | Standard |

| PSEN me3.1/2AR | Radius |

| PSEN me3.2/2AS | Standard |

| PSEN me3.2/2AR | Radius |

| PSEN me4/4AS | Standard |

| PSEN me4.01/4AR | Standard |

| Actuator type | Contacts | Supply voltage | Auxiliary release | Holding force | Extraction force | Order number |

| Standard | 24VAC/DC | u | 1,500 N | min.27 N | 570000 | |

| Standard | 110...230 VAC | u | 1,500 N | min.27 N | 570006 | |

| Radius | 24VAC/DC | u | 1,500 N | min.27 N | 570001 | |

| Standard | 24 VAC/DC | 1,500 N | min.27 N | 570004 | ||

| Radius | 24 VAC/DC | 1,500 N | min.27 N | 570005 |

| Contacts |

Contact load Utilization catrgory AC-15 |

Conventional thermal current | Extraction force | Order number |

| 240 V/1.5 A | 5A | 10 N | 570200 | |

| 240 V/1.5 A | 5A | 10 N | 570201 | |

| 240 V/3.0 A | 10A | 10 N | 570210 | |

| 240 V/3.0 A | 10A | 10 N | 570212 | |

| 240 V/3.0 A | 10A | 10 N | 570220 | |

| 240 V/3.0 A | 10A | 10 N | 570222 | |

| 240 V/1.5 A | 5A | 10 N | 570230 | |

| 240 V/1.5 A | 5A | 10 N | 570232 | |

| 240 V/3.0 A | 10A | 10 N | 570240 | |

| 240 V/3.0 A | 10A | 50 N | 570241 | |

| 240 V/3.0 A | 10A | 10 N | 570245 | |

| 240 V/3.0 A | 10A | 50 N | 570246 | |

| 240 V/1.5 A | 5A | 10 N | 570251 | |

| 240 V/1.5 A | 5A | 50 N | 570250 |

Order number for safety switch and actuator

(one unit)

Order number for safety switch and actuator

(one unit) Recommended type for the majority of applications

Recommended type for the majority of applications

Technical documentation on mechanical safety switches PSENmech:

Webcode 0314

Webcode 0314

Accessories, supplementary products and servives:

From page 62

From page 62

Webcode 0326

Webcode 0326

Online information at www.pilz.com

17

...highest level of safety at a low price

Non-contact, magnetic safety switches are used

to monitor the position of guards in accordance

with EN 60947-5-3 and also for general position

monitoring.

PSENmag gives you a cost- optimized system comprising

Pilz sensor and control system, including approval.

Maximum freedom for installation

The compact design of the PSENmag saves installation space. Connector and cable for all mounting and approach direc-tions, plus an assured operating distance of 3 or 8/10 mm, enable flexible assembly and rapid, simple installation.

High requirements — implemented economically

PSENmag switches can be used where a high category is specified, where there is heavy soiling or where strict hygiene regulations need to be met. The low wear and tear of the rugged, fully encapsulated housing, in conjunction with the non-contact, magnetic operating principle, guarantees a long product service life.

The optimum solution: Monitoring a cover using the PSENmag safety switches and the control systems PNOZmulti.

Keep up-to-date on non-contact,

magnetic safety switches PSENmag:

Webcode 0357

Webcode 0357

Online information at www.pilz.com

19

Common features

► Safety switches for monitoring Me position of movable guards in accordance with EN 60947-5-3

► Approved for applications up to Performance Level e of EN ISO 13849-1 and SIL CL 3 of IEC 62061 or up to Category 4 of EN 954-1 in

conjunction with:

- Safety relays PNOZsigma: PNOZ s3. PNOZ s4, PNOZ s5

- Configurable safety Systems PNOZmulti: All evaluation devices

- Programmable control systems PSS. with or wfthout SafetyBUS p interface: All evaluation devices

► Connected directly, via PDP67 or via the interface PSEN see accessories.

Sage 66 a Protection type:

- Cable versions: IP69K

- Connector versions: IP67

Type |

Assured switching distance |

PSEN ma1.4a-50/PSEN ma1.4-10 |

10 mm |

PSEN ma1.4a-51/PSEN ma1.4-10 |

10 mm |

PSEN ma1.4a-52/PSEN ma1.4-10 |

10 mm |

PSEN ma1.4p-50/PSEN ma1.4-10 |

10 mm |

PSEN ma1.4p-51/PSEN ma1.4-10 |

10 mm |

PSEN ma1.4p-52/PSEN ma1.4-10 |

10 mm |

PSEN ma1.4n-50/PSEN ma1.4-10 |

10 mm |

PSEN ma1.4n-51/PSEN ma1.4-10 |

10 mm |

PSEN 1.1a-20/PSEN 1.1-20 |

8 mm |

PSEN 1.1a-22/PSEN 1.1-20 |

8 mm |

PSEN 2.1a-20/PSEN 2.1-20 |

8 mm |

PSEN 2.1b-20/PSEN 2.1-20 |

8 mm |

PSEN 1.1p-20/PSEN 1.1-20 |

8 mm |

PSEN 1.1p-22/PSEN 1.1-20 |

8 mm |

PSEN 2.1p-20/PSEN 2.1-20 |

8 mm |

PSEN 2.1p-21/PSEN 2.1-20 |

8 mm |

PSEN 1.1b-23/PSEN 1.1-20 |

8 mm |

PSEN 1.1p-23/PSEN 1.1-20 |

8 mm |

PSEN 1.1p-25/PSEN 1.1-20 |

8 mm |

PSEN ma1.4a-50/PSEN ma1.4-03 |

3 mm |

PSEN ma1.4a-51/PSEN ma1.4-03 |

3 mm |

PSEN ma1.4a-52/PSEN ma1.4-03 |

3 mm |

PSEN ma1.4p-50/PSEN ma1.4-03 |

3 mm |

PSEN ma1.4p-51/PSEN ma1.4-03 |

3 mm |

PSEN ma1.4p-52/PSEN ma1.4-03 |

3 mm |

PSEN ma1.4n-50/PSEN ma1.4-03 |

3 mm |

PSEN ma1.4n-51/PSEN ma1.4-03 |

3 mm |

PSEN 1.1p-10/PSEN 1.1-10 |

3 mm |

PSEN 1.1p-12/PSEN 1.1-10 |

3 mm |

Contacts |

Single connection |

Series via |

LED |

ATEX |

Connection type Cable/connector |

Order number1) |

|

u |

- |

5m |

506322 |

||

|

u |

- |

u |

5m |

506326 |

|

|

PSEN ix1 |

5m |

506323 |

|||

|

u |

- |

M8, 4-pin, pigtall, 25cm |

506334 |

||

|

u |

- |

u |

M8, 8-pin, pigtail, 25cm |

506338 |

|

|

PSEN ix1 |

M8, 4-pin, pigtail, 25cm |

506335 |

|||

|

u |

PDP67 |

M12, 5-pin, pigtail, 25cm |

506342 |

||

|

u |

PDP67 |

u |

M12, 5-pin, pigtail, 25cm |

506343 |

|

|

u |

- |

5m |

504226 |

||

|

u |

PSEN ix1 |

5m |

504228 |

||

|

u |

- |

5m |

502226 |

||

|

u |

- |

10m |

502227 |

||

|

u |

- |

m8, 4-pin |

504220 |

||

|

PSEN ix1 |

m8, 4-pin |

504222 |

|||

|

u |

- |

m8, 4-pin |

502220 |

||

|

u |

- |

u |

m8, 4-pin |

502221 |

|

|

u |

- |

u |

10m |

504250 |

|

|

u |

- |

u |

M8, 4-pin |

504223 |

|

|

PSEN ix1 |

u |

M8, 4-pin |

504-225 |

||

|

u |

- |

5m |

506320 |

||

|

u |

- |

u |

5m |

506324 |

|

|

PSEN ix1 |

5m |

506321 |

|||

|

u |

- |

M8, 4-pin, pigtail, 25cm |